Following testing for almost a year, we have succeeded, together with Feralco and manure processor Mestverwerking de Kempen, in producing a new coagulant from our iron sludge. Coagulant is used as an agent for solid-liquid separation which, in this case, involves the thin and thick fractions of manure. Until now, this was only possible through the use of a chemical agent. Yet another attractive and sustainable application for aquafer.

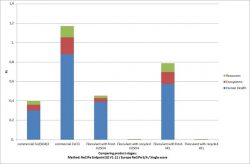

The coagulant we use at this location not only offers a financial benefit for agricultural companies, it is also much better for the environment. A life-cycle analysis (LCA) shows that its environmental impact is much lower than that of standard coagulants. The reason is that, apart from the use of iron as a secondary raw material, it also involves the use of a secondary acid.

Mestverwerking de Kempen is very satisfied with the results. This application leads to improvements in a number of the manure’s physical parameters, such as friability and dry-matter content. Last week a test-run was conducted at the Mestverwerking de Kempen installation and, on 23 February, the company will receive its first regular bulk delivery of iron sludge.

All in all, an interesting new market for aquafer which brings with it a solution to a societal problem. And, once again, a proof that aquafer can be reincorporated into a new (biological) loop as a high-value raw material. This development can moreover open the way to applications in other sectors, such as wastewater treatment or even in our own drinking water sector.